3D printing, also known as additive manufacturing technology, has its momentum in recent years. Based on digital model files, 3D printers are capable of using some cohesible materials like alloyed powder or non-metal stuff to construct a 3D model through a layer-by-layer printing method. First, 3D printers will analyze the online digital model files while processing them into slice pieces, and then according to the systematic route the printing head will move while extruding fused filaments out of the nozzle, and the machine will start constructing. FDM (Fuse Deposition Modeling) and SLA (Stereolithography) are the two most common printing technologies in this marketplace.

For beginners, FDM and SLA are the most appropriate methods for entering the 3D printing wonderland. As for those professional personnel, FMD and SLA are also the most welcomed ones popping up in this ever-developing technology. Although the different technologies can print out the same models, components, or let’s say, the same finished products as we wish, further details of the models out of different printing technologies still exist. Let’s just check out the differences between these two technologies.

Definition of FDM

The working principle of FDM is that the filament will be extruded by the extruder onto the platform, and then starts the printing process through piling up the melted filaments layer-by-layer till the final model is shaped. Various filaments can be adopted using this technology, like ABS, PLA, and other compounded materials mixed with multiple enhanced powders. So 3D printers adopting FDM possess a super wide range in this market with a broad 3D printing application.

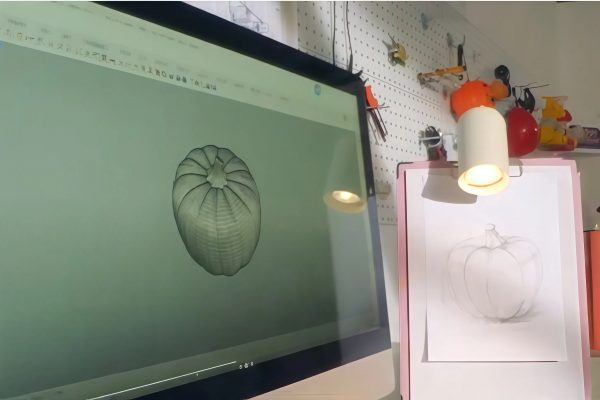

The Process of FDM- From Geeetech 3D Printer

Advantages of FDM

Compared with SLA, the FDM 3D printer has a far bigger construction size, it can design and print some practical components and models, and it can implement mass production in a small scale. A single type of 3D printing material generally has low resistance, low friction, high strength, and certain anti-corrosion properties, while composite materials generally refer to materials containing reinforced material powder or chopped fiber mixture in the main material, such as Carbonate and carbon fiber can be used to print stronger, lighter and dimensionally stable parts. FDM 3D printing ranges from model displays, and small replacement parts for automobiles to tooling fixtures for aerospace companies, making it a stronger choice for objects that require mechanical functions and performance. Some FDM 3D printers have high-precision printing characteristics so that the surface of the printed parts is smooth and uniform, which can meet the general use test requirements.

Downsides of FDM

Confined by its low-resolution power, finished products or models made by the conventional 3D printers of FDM will sometimes come with some unavoidable lines on their surfaces. And these sorts of “flawed” models require some additional polishing process to remove the residues. Besides, temperature fluctuation is also the most common problem existing in the FDM 3D printing process, which might cause a clumsy and slow-down action to cool down the filament.

Promising Side of SLA

Compared with FDM, the most promising factor that SLA prevails is that it can realize a 25 microns resolution power at its lowest, as a result, it makes the product smoother with a more delicate detail. In this sense, it can rival and compete with the traditional injection molding, while bearing a great resemblance with it on their finished products. This kind of application is quite suitable for producing some certain products for displaying, concept models, organic structures, components with more complex geometric configurations, other sculptures, and unique gadgets and novelties. Adopting UV light as its core aligning component, SLA 3D printers possess a minor error in the printing process.

Shortcomings of SLA

Because cured resin materials feature brittleness, only certain formulas of industrial SLA resin can be applied to bear the mechanical stress or the components of cyclic loading. Besides, most standard resins are quite suitable for producing any model products with fine structure and high surface smoothness. Speaking of solidity and mechanical properties, there still exists no SLA resin materials that can rival polycarbonate, nylon, and other solid FDM materials currently. In addition, when it comes to the prime cost, resin material will cost much more than other sorts of materials. Plus, compared with FDM 3D printers, SLA printers can only produce models of smaller sizes and can’t be applied to mass production.

GEEETECH DP200